¿Puede una máquina bobinadora de láminas para transformadores manejar conductores de aluminio y cobre y múltiples tipos de aislamiento?

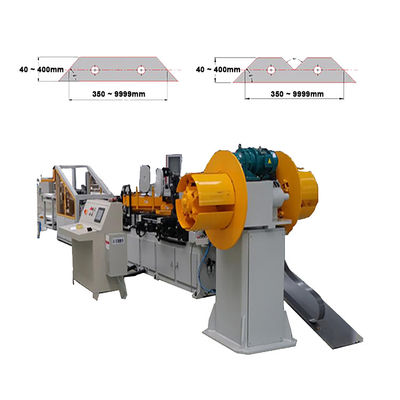

En un panorama de fabricación competitivo, la flexibilidad y la utilización de los activos son primordiales. Un fabricante de transformadores a menudo debe producir bobinas utilizando diferentes materiales conductores (cobre o aluminio) y una variedad de tipos de aislamiento, dependiendo de las especificaciones del cliente, los parámetros de costos y los requisitos térmicos. Esta diversidad operativa plantea una pregunta práctica para la inversión de capital: ¿Puede una máquina bobinadora de láminas para transformadores moderna y de alto rendimiento diseñarse con la versatilidad necesaria para manejar eficientemente conductores de cobre y aluminio, junto con varios materiales de aislamiento, sin comprometer la precisión ni requerir un tiempo de cambio excesivo?

La respuesta reside en la modularidad y la ingeniería sofisticada de los sistemas de manejo y tensión de materiales, que deben construirse con la adaptabilidad suficiente para gestionar las propiedades muy variables de estos materiales.

Gestión de diferentes materiales conductores (cobre vs. aluminio):

El cobre y el aluminio presentan desafíos distintos para la maquinaria de bobinado. El aluminio es más ligero, más blando y tiene una menor resistencia a la tracción que el cobre. Esta suavidad significa que el aluminio es más propenso a estirarse, reducirse y ceder si se aplica una tensión excesiva. El cobre, aunque más fuerte, es más pesado y requiere más par para gestionar su inercia.

Una máquina bobinadora de láminas muy versátil aborda estas diferencias a través de:

Sistemas de tensión electrónica de doble rango: La máquina debe estar equipada con un sistema de control de tensión electrónico que ofrezca una amplia gama programable de valores de tensión. El software de control debe permitir al operador cambiar instantáneamente entre el perfil de tensión requerido para el cobre robusto y el perfil de tensión significativamente más bajo y sensible requerido para el aluminio, evitando daños y deformaciones del material más blando.

Superficies de contacto especializadas: Las guías, rodillos y células de carga que entran en contacto con el conductor deben ser tratadas o recubiertas para que no dejen marcas. Esto es especialmente importante para el aluminio, que se raya o daña fácilmente, creando potencialmente puntos de tensión. A menudo se emplean superficies no ferrosas anodizadas duras o pulidas para garantizar un desplazamiento suave y sin daños.

Desbobinado de alta capacidad: Para manejar las bobinas de aluminio potencialmente más grandes y pesadas (debido a su menor densidad que requiere un mayor volumen para la misma capacidad de transporte de corriente) y la alta inercia de las bobinas de cobre pesadas, el desbobinador debe contar con rodamientos de alta resistencia y potentes sistemas de frenado dinámico capaces de gestionar la inercia de ambos extremos.

Manejo de múltiples tipos de aislamiento:

Los fabricantes de transformadores utilizan varios materiales de aislamiento entre capas, incluyendo papel fino, película de Mylar o películas más gruesas de Nomex/Kapton, cada uno con requisitos de manejo únicos basados en su rigidez, resistencia al desgarro y grosor.

La máquina debe contar con un sistema de alimentación de aislamiento modular y adaptable:

Estaciones de bobina múltiple: La máquina debe integrar al menos dos, y a menudo más, estaciones de desbobinado de aislamiento independientes. Esto permite el bobinado simultáneo de múltiples capas (por ejemplo, una capa primaria delgada y una capa protectora más gruesa) o el cambio rápido entre diferentes materiales sin intercambiar físicamente las bobinas.

Tensión de borde ajustable: A diferencia del conductor, el material de aislamiento normalmente requiere una tensión más baja para evitar el desgarro. Los sistemas de alimentación de aislamiento deben tener su propio control de tensión independiente y altamente sensible, que a menudo emplea brazos bailarines sin contacto o frenos magnéticos de baja fuerza para gestionar con precisión las delicadas películas.

Prevención de pliegues y arrugas: Se deben emplear rodillos guía de cara ancha y barras separadoras especializadas cerca del punto de bobinado para aplanar y eliminar suavemente cualquier arruga o pliegue de la película antes de que se coloque. Una arruga en el aislamiento crea un espacio de aire, lo que puede provocar una falla dieléctrica prematura bajo tensión de voltaje.

En resumen, una máquina bobinadora de láminas para transformadores moderna logra versatilidad a través del control electrónico sofisticado y un diseño de hardware modular. Al integrar sistemas de tensión de amplio rango controlados independientemente, superficies de contacto especializadas que no dejan marcas y alimentaciones de aislamiento de bobina múltiple flexibles, una sola máquina puede cambiar de manera confiable entre las demandas de bobinado de aluminio blando y cobre robusto, al tiempo que se adapta a varios tipos de aislamiento. Esta multifuncionalidad maximiza el retorno de la inversión de un fabricante y proporciona la agilidad operativa necesaria para satisfacer las diversas especificaciones del mercado global de transformadores.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!